There are many stories about weapons with names, Authur’s sword, various Japanese katana, video game weapons (BFG). How does this happen? Well a year ago, at the renaissance festival where I demonstrate bow making, I have several on display. English longbows and horse bows. A patron asked about the maker of the horse bows. The maker was a man named Atilla and I have several of his bows. The patron informed me that Atilla closed up his shop and moved back to Hungary. The last few years had killed his business. Seems these bows are now prized. I will miss Atilla and his work. While this conversation is going on, another member of the militia (who is an old friend and real jerk) made the offhand comment I should make my own. This challenge sunk in, and so now I introduce Rippington!

Here is Rippington, ready for action!

A traditional horse bow was made of horn from water buffalo, wood or bone, sinew, and hide glue. This is a kit from www.bowskin.com. The kit is $140.00 US. It comes with a carbon fiber/fiberglass core, to ends (syahs), a handle, super sinew, 2 sets of 2 part Fasco Epoxy glue, a string, and some instructions. The instructions are a bit sparse, so I have built this blog for more details.

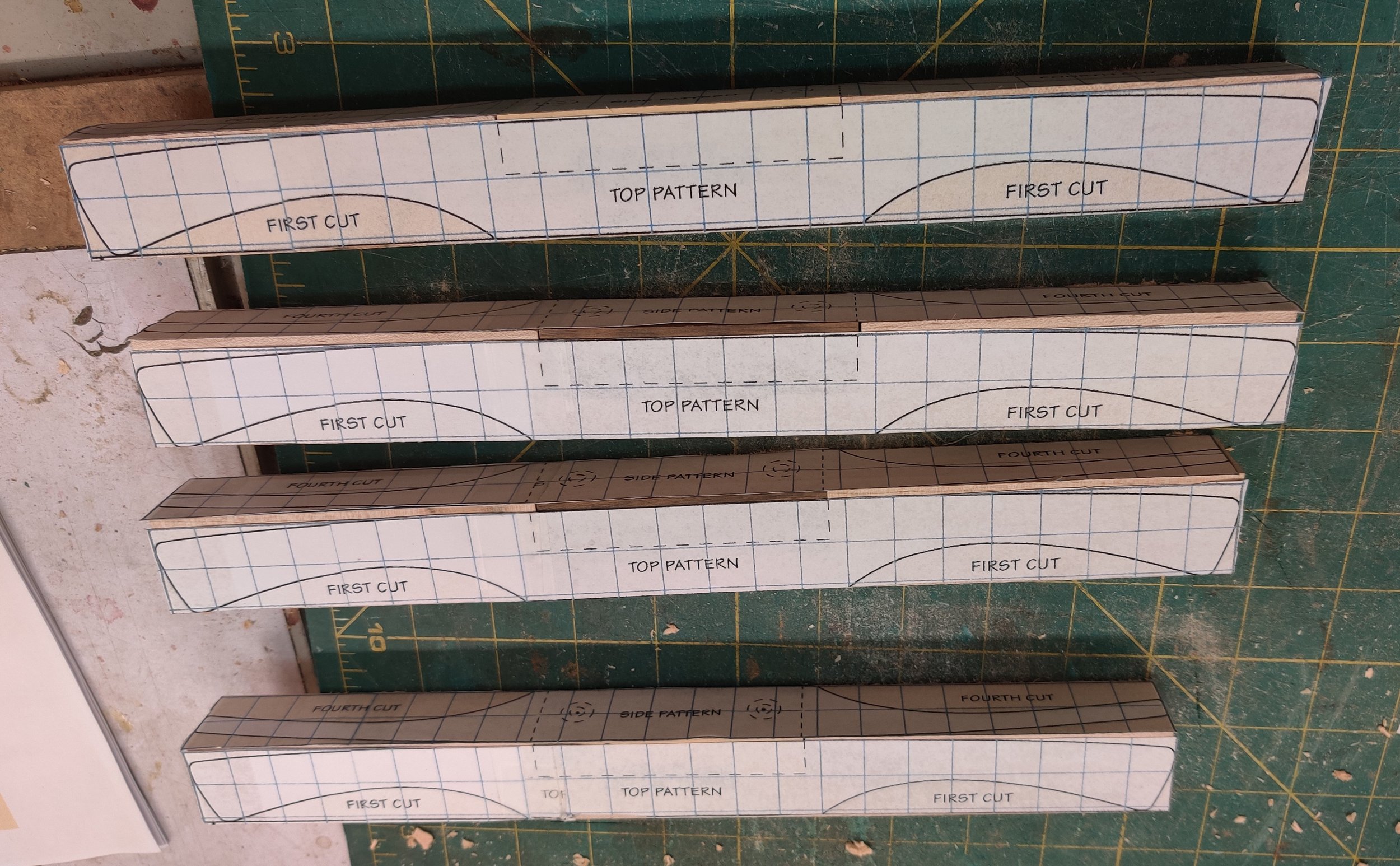

The hard parts

Prepping for glue up

This is my bow bench in my shop. I have a vise held in the side vise of my woodworking bench and a stand held in my end vise.

The glue up. The Facso epoxy glue is amazing stuff. https://fascoepoxies.com/Fasco-110-Epoxy-Glue.html

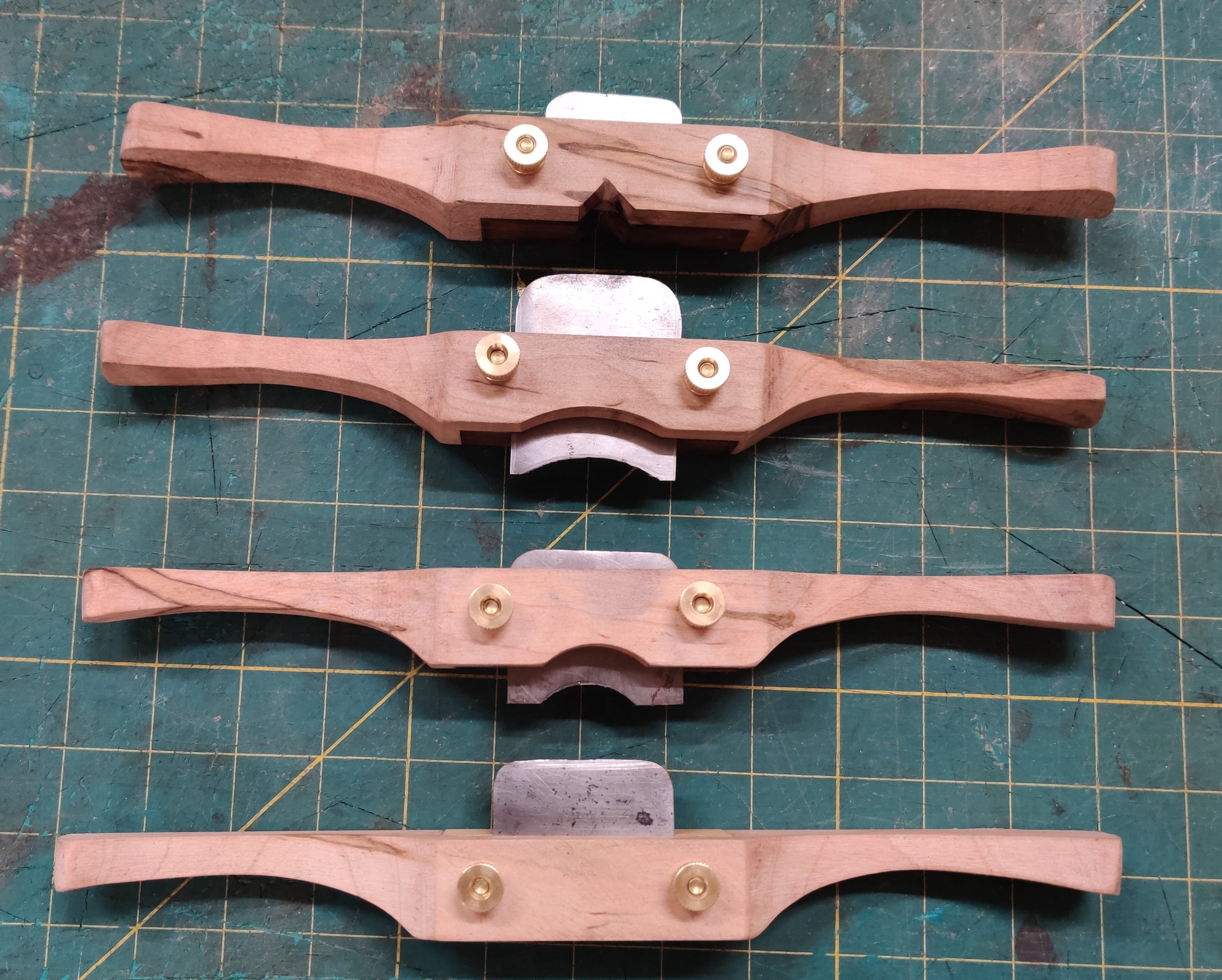

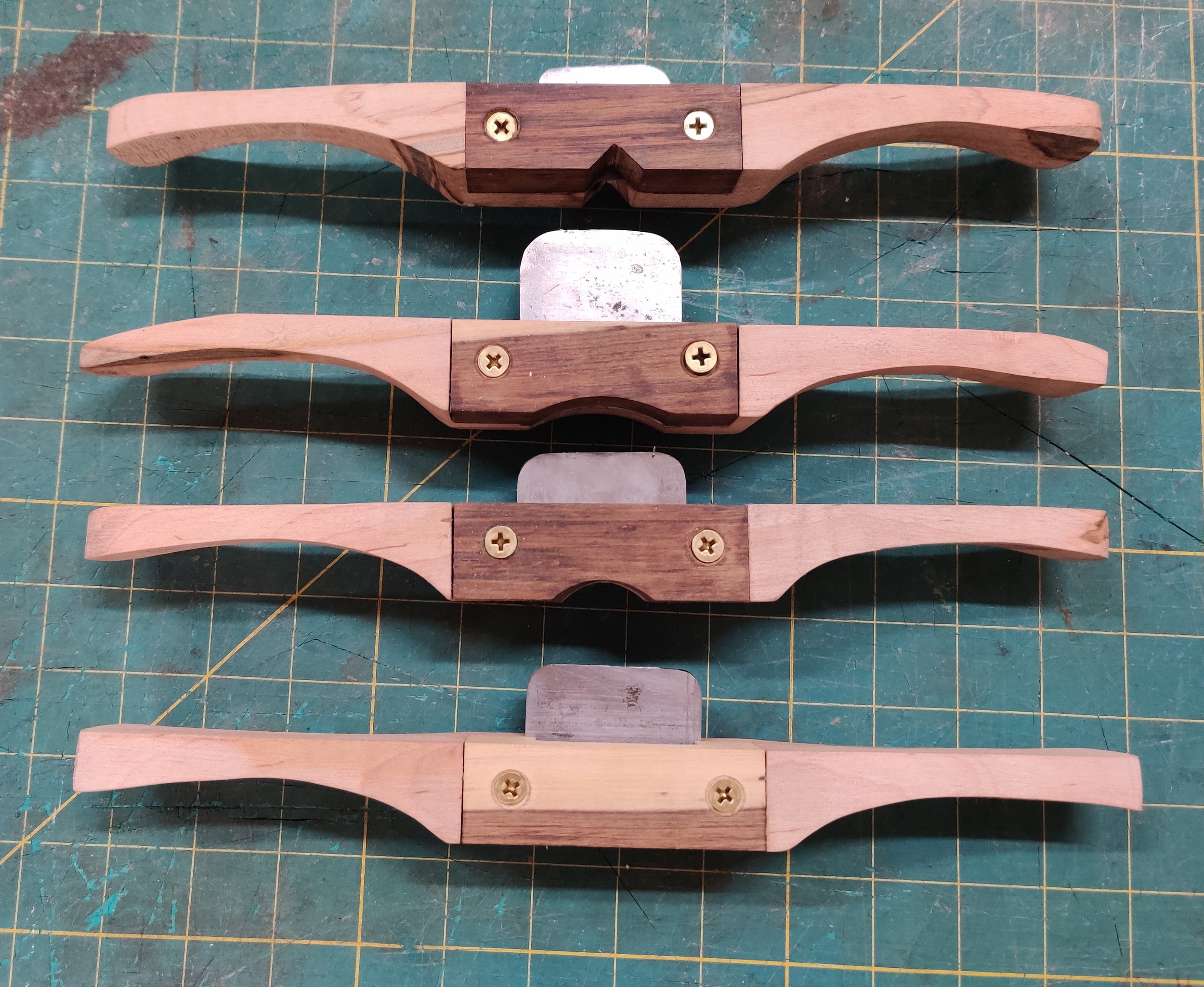

A set of bow makers tools. At the top I have several rasps. You can use any you have at hand. I started with a farriers file from a farm store. I have upgraded over time. The top rasp is by Dean Torges. The three in the middle are pattern makers rasps. Then there is a chain saw file for making string knocks. Below that is a scraper from Dean Torges as well. Then three card scrapers and a piece of buffalo horn for burnishing.

Being a bow maker (bowyer) I have all the hand tools to build bows. Using rasps and scrapers I make a first pass at glue cleanup and shaping of the bow.

The next step mirrors how a traditional horse bow would be built. All the glue up would be reinforced with hide glue in sinew. In this case, the kit provides “super sinew” and epoxy glue.

After the “super sinew” glue up, there is another round of cleanup with hand tools.

Now to start dressing the bow to make it look more “period”. I am going with a blue artificial sinew wrap.

How long should a string be? The normal length of the string is determine by finding the brace. You string the bow with a test string. Then measure from the handle to the string using a thumbs up. This is called a festmele. It is the proper distance for you.

Strung Bow

Festmele

There are two types of bow strings, a Flemish string and an endless string. Horse bows generally us an endless style. This requires a jig. The video is an example build.

One side

Full set up

Time to finish the bow. An arrow rest and handle.

Tine to answer the real question. Does it shoot?

If you do all the work, give yourself some credit. Sign your work!

As a coda on this build, the kit is good quality, the directions a not great, my bows draws 28# at 28 inches. I don’t think it will be 50# at 32 inches. It is nice to shoot and delivers a crisp arrow. I am glad I found the kit.